April 12, 2024

Tokyo startups eye US market for expansion

Recent News

- May 7, 2024

eNuvio co-founder Mark Aurousseau and Mirus Bio COO Geoff Schwartz on the VatorNews podcast

Mirus develops products for life science research, while eNuvio creates devices to simulate the body

- May 6, 2024

Babson Diagnostics and Cynergy partner on consumer-initiated orders of its BetterWay blood test

BetterWay blood testing will launch in Texas later this year before rolling out nationally

- May 6, 2024

Value-based MSK platform Livara raises $15M

The round brings Livara's total funding to $27 million raised to date

- May 3, 2024

Owlet receives clearance to sell its baby monitoring tech in the EU

Dream Sock is an over the county monitor offering live health readings and notifications for infants

- May 2, 2024

Transcarent raises $126M to accelerate AI capabilities

This round values the company at $2.2 billion

- May 2, 2024

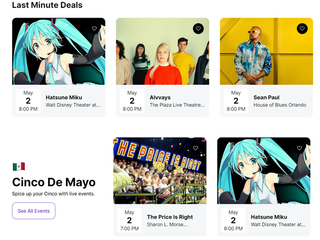

Perseverance: From running out of money to an IPO - StubHub comes back strong

In the post-Covid drive for live events, ticket platforms are jumping at the opportune market time

- May 2, 2024

Genoscience co-founder Jean Gekas, and genetic counselor Claire Bascunana, on the VatorNews podcast

Genocience is a group of private clinics offering genetic screening and fertility services

- May 1, 2024

Every Cure and BioPhy launch partnership on drug repurposing

EveryCure will leverage BioLogicAI, BioPhy’s predictive AI engine, to assess drug-disease matches

- May 1, 2024

Credentialing automation platform Baton Health launches Universal Primary Source database

That gives its customers access to hundreds of PSV databases through a single query

- April 30, 2024

Autonomous blood drawing device developer Vitestro raises $22M

The company plans to bring its device to market in Europe before expanding to the United States

- April 29, 2024

Washington state selects Fusion Health as its official EHR vendor

The contract will make it easier for state agencies to evaluate and implement Fusion's technology

- April 29, 2024

OpenAI goes to Tokyo to resolve LLM struggles with Japanese language

The new office marks OpenAI's first location in Asia

- April 29, 2024

Meet John Beadle, co-founder and managing partner at Aegis Ventures

Aegis Ventures works with health systems to build and invest in digital health companies

- April 26, 2024

Thirty Madison and Talkspace join forces to expand mental health access for women

Talkspace will be the therapy partner for femtech brand Nurx and migraine treatment platform Cove

- April 26, 2024

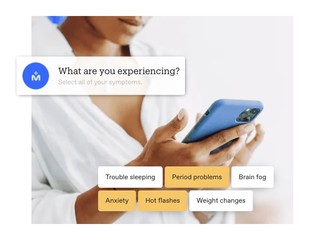

Midi Health, a virtual care clinic for women's health, raises $60M

Midi is currently on track to serve about 100,000 patients this year, up from about 30,000 in 2023

Sign up now to subscribe to our newsletter and stay up to date with the latest news!

Featured News

X to charge new users for interaction in battle against the bots

- By Anna Vod

- |

- April 25, 2024

New disease models unlocking secrets to neurological research

- By Steven Loeb

- |

- April 23, 2024

Tokyo startups eye US market for expansion

- By Kym McNicholas

- |

- April 12, 2024

Which large corporations are leading the charge in warehouse automation?

- By Steven Loeb

- |

- April 12, 2024

Healthtech investing still lags behind even as funding grew 42% in Q1

- By Steven Loeb

- |

- April 8, 2024